Quarry Tile Flooring

When it comes to choosing the right type of tile for your business or even your home, there are many options to consider. One popular choice is quarry tile, which is favored by operators of demanding industries, such as commercial kitchens and food processing facilities.

Quarry tile is chosen for such applications because of its durability and resistance to moisture. However, not all quarry tiles are created equal. This blog post will compare Metropolitan Ceramics quarry tile to other manufacturers’ options. Let’s look at the Metropolitan Ceramics difference.

What Is Quarry Tile?

Quarry tile is a type of floor tile that is made from natural clay and shale. It is known for its hardness and ability to withstand extreme temperatures and moisture, which make it a popular choice for high-traffic areas like commercial kitchens, hallways and entryways, food processing plants, breweries, convenience stores, and more. It is a type of ceramic tile that is unglazed, which gives it a natural, rustic look. Quarry tile has a vitreous nature, making it suitable for outdoor applications as well. High-quality quarry tile, such as that from Metropolitan Ceramics also features a dynamic coefficient of friction well above the industry guideline of .42, helping to prevent slips and falls.

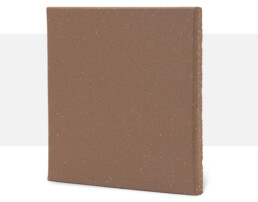

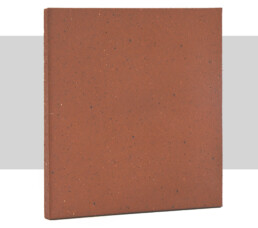

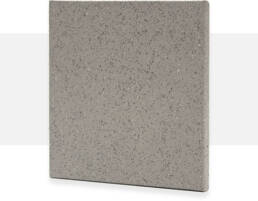

Quarry tile is produced in a variety of colors, from earthy browns, tans, and reds to more modern shades like gray and black. The tiles are solid, with the color running through the body of each tile.

Extruded vs. Pressed Quarry Tile

The method used to produce a quarry tile makes a big difference when it comes to its strength and quality. There are two ways to manufacture quarry tile: extrusion and pressing. Extruded quarry tile is made by forcing clay through a die. This process contributes to the product’s life expectancy of 50 years or more.

Pressed quarry tile is made by compressing clay into molds. This process can result in slight variations in size and thickness — a look some homeowners prefer. Both types of quarry tile are functional, but there are some differences to consider when choosing a tile.

Metropolitan Ceramics quarry boasts uniformity in size and thickness, which makes it easier to install evenly. Because of the pressure placed on the clay during the extrusion process, it is also less likely to have imperfections, such as air pockets or cracks, which can compromise the tile’s strength. Pressed quarry tile is less dense than extruded tile, which can compromise its durability and ability to resist moisture.

Another important difference when it comes to quarry tile strength is thickness. Metropolitan Ceramics quarry tiles have a thickness of ½ inch, whereas many other tiles have a thickness of only ¼ or ⅛ inches. The extrusion process, a method that Metropolitan Ceramics company has used in brick and tile making for more than 150 years, creates an extruded quarry tile that outperforms its pressed alternatives.

Metropolitan Ceramics Offer More Types of Quarry Tile

Metropolitan Ceramics offers four quarry tile product lines through our professional distributor networks:

QuarryBasics® Ironspot: Integrates small iron particles throughout the tile body, resulting in a subtle speckled appearance, while still maintaining a Dynamic Coefficient of Friction ≥ .60 at time of manufacture. The unique blend of durability, along with a focus on safety and appearance, positions QuarryBasics Ironspot as the preferred option for demanding projects.

QuarryBasics® XA Abrasive: All the durability and slip-resisting properties of our QuarryBasics® line with a silicon-embedded surface and a metallic additive through the body of the tile to create a one-of-a-kind tile with added slip-resisting properties. This line is appropriate for the most challenging environments where slip prevention is essential.

The Metropolitan Ceramics Quarry Tile Investment

Metropolitan Ceramics puts its quarry tiles through rigorous testing so that we can offer a commercial flooring product that will remain undamaged and retain its aesthetics and safety characteristics for decades. The exceptional technical characteristics of our quarry tiles make them appropriate for virtually any application suitable for tile. We meet or exceed ASTM standards in 13 areas including abrasion resistance, breaking strength, freeze/thaw, shear bond strength, chemical resistance, stain resistance, and scratch hardness.

This means that quarry tile from Metropolitan Ceramics is your best investment when it comes to commercial flooring for challenging environments. Contact us to learn more about Metropolitan Ceramics quarry tile lines or find a distributor of our products.