Quarry Tile Features and Benefits

Extremely durable slip resisting tile for demanding applications.

Quarry Tile Features & Benefits

Extremely durable slip resisting tile for demanding applications.

Why Quarry Tile?

Durable and slip resisting, Metropolitan Ceramics quarry tile is engineered for commercial kitchens and other demanding spaces. Many building owners are unaware of what sets Metropolitan Ceramics tile apart from other floor covering used in heavy-duty commercial applications. Metropolitan Ceramics tile is unglazed and extruded. The tiles are hard-fired to be very low absorption – less than 3%. Metropolitan Ceramics quarry tile is ready for demanding environments, areas with temperature extremes, heavy traffic and spills of all kinds.

Unglazed Surface

Metropolitan quarry tile products have a tight die skin surface with a "slight orange peel” natural slip resisting surface. The tiles have a coefficient of friction ≥ .60. Added slip resistance products are also available.

Half Inch Thickness

The tiles are thicker than most ceramic tile. They are extruded ½” thick for added durability. When the extruded low absorption tiles are fired at temperatures exceeding 2,000° Fahrenheit, it creates a very hard/dense body.

Freeze Thaw Stable

You can use Metropolitan Ceramics' unglazed tile outdoors in any climate. Use over a concrete slab for walkways, patios and other hardscape areas. Think of Metropolitan indoors around ovens, under fryers and in walk-in freezers.

Extruded & Hard Fired

With a life expectancy of fifty years and more, you won’t have to worry about replacing your Metropolitan Ceramics' quarry tile floor at any time soon – and that longevity saves you the money and hassle of replacing your floor every few years.

Relieved Edges

There is a relieved – cushioned – edge on Metropolitan tile for a reason. The rounded edge is created when the tiles are extruded from a die. It’s there to help protect the tile from chipping from carts or when something is moved across the floor.

Low Absorption

Metropolitan Ceramics' quarry tile is extruded and fired in kilns at high temperatures creating a tight die skin and vitreous – less than 3% absorption - body. The low absorption body will resist staining in restaurant kitchens and other areas where spills of all sorts are common.

Tested & Approved

All Metropolitan Ceramics’ unglazed quarry tile has gone through ASTM testing so that you can have confidence your commercial floor will perform the way you expect it to. Other flooring options sold as heavy duty commercial or industrial may not be able to make this claim. Do you really want to rely on a floor covering product that has not gone through stringent testing?

ASTM C1243

Abrasion Resistance

STANDARD:

Maximum Value of 275 mm3

Metropolitan Tests at <275mm3

ASTM C373

Absorption 5-Hour Boil

STANDARD:

Maximum 5%

Metropolitan tests at 3% maximum and qualities as vitreous

ASTM C648

Breaking Strength

STANDARD:

Maximum Value of ≥250 lbf

Metropolitan tests at 400 lbf or better

ASTM C499

Thickness

STANDARD:

Max. range of .050

Metropolitan meets the standard

ASTM A137.1

DCOF ACU Test (wet)

STANDARD:

No industry standard threshold of 0.42

All Metropolitan products exceed 0.60

ASTM C1026

Freeze/Thaw

STANDARD:

Observations after 300 cycles. No visible damage.

Metropolitan meets the standard

Quarry Tile The Most Economical of all Floor Finishes

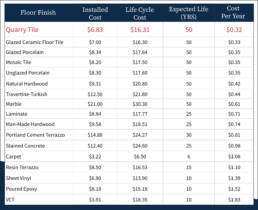

Metropolitan Ceramics® quarry products are one of the longest lasting flooring products available. In fact, a study conducted by the Tile Council of North America found quarry tile to be the best value among competing floor covering products based specifically on the price and longevity of the product.*

Cradle to Cradle is fast becoming the standard by which the sustainability of building products is measured. This concept puts focus on the entire life cycle and re-use of a product. Metropolitan® quarry tile is an excellent cradle-to-cradle product because it is mined at close proximity to the manufacturing site and it can last for many years and even centuries. At the end of a building’s life, it can be removed and reused as tile or be recycled as a roadbed material with no negative impact on the environment.

*The Tile Council Of North America commissioned an independent construction cost consulting firm, Scharf-Godfrey (a Division of Phoenix Engineering Inc.), to conduct a Life Cycle Cost study comparing various types of ceramic tile including glazed and unglazed, porcelain, mosaic, and quarry tile to twelve other floor finishes such as hardwood, laminate, concrete, stone, carpet, terrazzo, vinyl and poured epoxy.

Cleaning Made Easy

Proper cleaning and maintenance is important for commercial kitchen flooring. Unlike other commercial flooring options quarry tile can be properly maintained with routine cleanings using neutral cleaners.

1

Sweep

Sweep entire area of floor to be cleaned with a broom. Use dust pan to pick up dirt and debris.

2

Scrub

To remove grease and stubborn stains on commercial kitchen floors, scrub floor with deck brush using clean HOT water and a neutral cleaner.

3

Mop

Dip a clean synthetic mop into clean HOT water. Wring out the mop to the point it’s well saturated, but not dripping.

Repeat

Repeat steps 1, 2, and 3 until the entire floor is clean.

Remember to change the water as it becomes dirty.