Environmental Impact & Stewardship

Metropolitan Ceramics Quarry Tile is suitable for the most demanding environments including; Craft Breweries, Commercial Kitchens, Schools, Industrial Applications, Supermarkets, or anywhere slip resistance and durability are a must.

Metropolitan Ceramics and the Environment

Ironrock is committed to providing our customers with sustainable products while keeping with the company’s commitment to good stewardship toward the environment and our community. This page gives more insight into the steps we are taking to save resources and energy in the manufacture of Metropolitan Ceramics’ quarry tile and thin brick products.

We will also look at the positive environmental impact Metropolitan Ceramics’ quarry tile products have once installed, for the life of their use and beyond. We will look at testing for durability, product life cycle, indoor air quality and recycled content.

Finally, this page includes downloadable PDFs on health product declaration (HPD) and environmental product declaration (EPD) for all Metropolitan Ceramics’ quarry tile and thin brick products.

Ironrock products are listed in the mindful Materials database

Mindful MATERIALS is a free platform with aggregated information on human health and environmental impacts for products from leading manufacturers, vetted by experts passionate about making it easier to make informed product choices.

Products that are accepted into the database must undergo a vigorous vetting process to insure the products meet health and sustainability standards.

* Once you go to mindful Materials’ website you can create a FREE account to access all of the database’s features.

The Manufacturing Process

Mined Locally

Over 90% of raw materials are mined within 50 miles of our facility.

Recycled Waste Clay

Over 3,000 tons of waste clay is recycled back into production annually.

Heat Source

The heat from our kilns is also a heat source for our dryers.

Fired Scrap

Over 700 tons of fired scrap are recycled into our products each year.

Shipping Cartons

All shipping cartons contain recycled material and all cartons are recyclable.

Production Equipment

We use the most energy efficient production equipment available.

Durability Testing Data

Manufactured for long wear in demanding applications, Metropolitan Ceramics® unglazed ceramic quarry tile meets or exceeds the following standards relating to sustainability.

ASTM C1243

Abrasion Resistance

STANDARD:

Maximum Value of 275 mm3

Metropolitan Tests at <275mm3

ASTM C373

Absorption 5-Hour Boil

STANDARD:

Maximum 5%

Metropolitan tests at 3% maximum and qualifies as vitreous

ASTM C648

Breaking Strength

STANDARD:

Maximum Value of ≥250 lbf

Metropolitan tests at 400 lbf or better

ASTM C499

Thickness

STANDARD:

Max. range of .050

Metropolitan meets the standard

ASTM C1026

Freeze/Thaw

STANDARD:

Observations after 300 cycles. No visible damage.

Metropolitan meets the standard

ASTM C499

Nominal Size

STANDARD:

The facial dimension of each tile in the sample shall not vary more than ±2.00% from the nominal dimension.

Metropolitan Meets the Standard

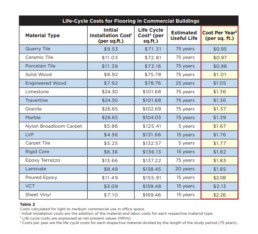

*The Tile Council Of North America commissioned an independent construction cost consulting firm, Scharf-Godfrey (a Division of Phoenix Engineering Inc.), to conduct a Life Cycle Cost study comparing various types of ceramic tile including glazed and unglazed, porcelain, mosaic, and quarry tile to twelve other floor finishes such as hardwood, laminate, concrete, stone, carpet, terrazzo, vinyl and poured epoxy.

Sustainability

Metropolitan Ceramics® quarry products are one of the longest lasting flooring products available. In fact, a study conducted by the Tile Council of North America found quarry tile to be the best value among competing floor covering products based specifically on the price and longevity of the product.*

Cradle to Cradle is fast becoming the standard by which the sustainability of building products is measured. This concept puts focus on the entire life cycle and re-use of a product. Metropolitan® quarry tile is an excellent cradle-to-cradle product because it is mined at close proximity to the manufacturing site and it can last for many years and even centuries. At the end of a building's life, it can be removed and reused as tile or recycled as a roadbed material with no negative impact on the environment.

Indoor Air Quality

During Installation and Once Installed the low absorption, kiln-fired, natural materials that make up Metropolitan® quarry tile produce NO VOC’s sometimes associated with other flooring products. Metropolitan Ceramics® quarry tile is neither an ‘original source’ nor a source for ‘absorbed’ volatile organic compounds. Metropolitan® quarry tile will not contribute to the growth of mold or bacteria. Metropolitan Ceramics® quarry tile can be installed and sealed with low VOC products, providing air quality advantages during installation. Floor coverings make up a large percentage of surface space in a building, and a Metropolitan® quarry tile floor, when properly installed and maintained, will help contribute to a healthy work and living environment.

Other possible sources of VOCs are the cleaning products required to clean some surface materials. Metropolitan Ceramics® quarry tile can be cleaned using non-toxic, water based cleaners.

To learn more about the clean air benefits of tile visit whytile.com.

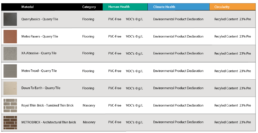

Recycled Content

Metropolitan Ceramics® re-uses waste materials in the production of its unglazed ceramic quarry tile. The following chart contains percentages of pre-consumer recycled material in Metropolitan Ceramics’ products.

- 108 Chestnut Brown | 25%

- 710 Raven | 27%

- 31XA Mayflower Red | 26%

- 57XA Puritan Gray | 28%

- 350 Red Paver | 26%

- 458 Bedrock | 25%

- 155 Cobblestone | 29%

- 255 Desert Floor | 23%

Metropolitan Ceramics®

Quarry Tile

- 108 Chestnut Brown | 25%

- 710 Raven | 27%

- 31XA Mayflower Red | 26%

- 57XA Puritan Gray | 28%

- 350 Red Paver | 26%

- 458 Bedrock | 25%

- 155 Cobblestone | 29%

- 255 Desert Floor | 23%

Green Documents

Metropolitan Ceramics’ products have the documentation required for LEED accreditation of your building project. These include Green Squared product standard ANSI A138.1– a third-party multi-attribute certification, an Environmental Product Declaration (EPD), and a Health Product Declaration (HPD). You can download documentation for each below.

Environmental Product Declaration (EPD)

Ironrock has taken part in an industry-wide Environmental Product Declaration – EPD. The EPD reports the environmental footprint of North American made ceramic tile across all major impact categories within a 60 year building service life. This EPD is an initiative of the Tile Council of North America. Use the EPD to fulfill requirements of leading green building programs.

Material Ingredients Guide (Industry Wide)

Ironrock is a participating manufacturer in the Tile Council of North America (TCNA) Material Ingredient Guide (MIG). The MIG is the result of a North American tile industry collaboration, led by WAP Sustainability through the support of TCNA and its members. It is a resource for ceramic tile, mortar, and grout manufacturers to use when providing the content and chemical makeup of their products or “material ingredient transparency”.