Unglazed Quarry Tile: Durable & Stylish Choice for Commercial Kitchens

When choosing flooring for a commercial kitchen, durability, strength, and safety are some of the most important factors. Because unglazed quarry tile earns high marks in these three areas, it is a popular choice for commercial kitchens. It is also a versatile and stylish option that can help you achieve a variety of looks. This blog will explore the numerous benefits of using six-inch unglazed quarry tile for commercial kitchen flooring.

What is Unglazed Quarry Tile?

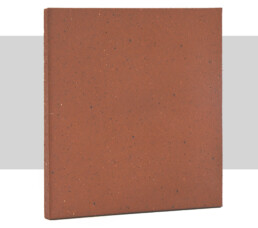

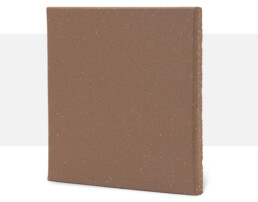

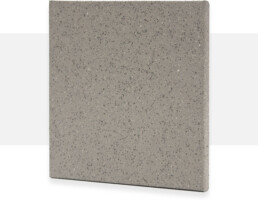

Quarry tile is a type of ceramic tile that is made from a dense mixture of clay and shale. It is fired at high temperatures to create a tile that is durable and resistant to stains, moisture, and heavy traffic. Unglazed quarry tile is available in many colors, but it is most commonly found in natural earth tones such as red, brown, black, and gray.

Unlike glazed ceramic tiles which have a shiny surface, unglazed quarry tiles have a matte finish. This unique texture not only adds to its aesthetic appeal but also enhances its slip-resisting properties.

While the most common size of quarry tiles is a 6’’ x 6’’ quarry tile (also sometimes referred to as 6’’ x 6’’ commercial kitchen tile), they come in other sizes and shapes as well.

The Benefits of Unglazed Quarry Tile for Commercial Kitchens

There are many benefits to using unglazed quarry tile in commercial kitchens, including:

- Durability: Unglazed quarry tile is one of the most durable and dense tiles available. Designed to withstand high foot traffic, heavy equipment, spills, and constant cleaning. It is resistant to chipping, scratching, and cracking, making it ideal for areas such as commercial kitchens.

- Resistance against slips and falls: Unglazed quarry tile also helps to prevent slipping, even in the most demanding kitchens. This is an important safety feature for commercial kitchens, where grease and other spills are common. Unglazed quarry tile can help to reduce the risk of accidents and injuries.

- Easy cleaning and maintenance: Unglazed quarry tile is easy to clean and maintain. It does not require any special sealants or waxes, and it can be cleaned with a simple mop and bucket. Quarry tile’s low absorption rate prevents moisture from seeping into the tile, preventing mold and mildew growth.

- Variety of colors, shapes, and sizes: New products can help create a variety of looks. This makes it a versatile choice for commercial kitchens of all styles.

6’’ x 6’’ Unglazed Quarry Tile for Commercial Kitchens

6’’ x 6’’ unglazed quarry tiles are a popular choice for commercial kitchens because of their size and versatility. They are large enough to create a durable and easy-to-clean floor, but also small enough to be easily and quickly installed, reducing downtime for the kitchen.

6’’ x 6’’ quarry tile can be set in both a checkerboard or running bond pattern, or, with rectangular quarry tiles, it can be used to create a variety of patterns. It can also be used to create borders and accents.

Tips For Choosing and Installing Unglazed Quarry Tile For Commercial Kitchens

When choosing unglazed quarry tile for a commercial kitchen, it is important to select a tile that is rated for commercial use. This will ensure that the tile is durable enough to withstand the rigors of a busy kitchen environment.

Unglazed quarry tile can be installed by a qualified tile installer. The tile is typically installed using a thinset mortar. After the tile has been installed, it should be sealed with a grout sealer.

Maintenance and Cleaning

Unglazed quarry tile is a low-maintenance flooring option. It can be cleaned with a simple mop and bucket and does not require any special sealants or waxes.

To clean unglazed quarry tile, simply mop with a mild detergent and water. Avoid using harsh chemicals or abrasive cleaners, as these can damage the tile.

To seal the grout, use a grout sealer that is specifically designed for unglazed quarry tile. Apply the sealer according to the manufacturer’s instructions.

Cost Considerations and ROI for Unglazed Quarry Tile

When considering commercial kitchen flooring options, cost is important. Let’s examine the upfront cost of unglazed inch unglazed quarry tile and its potential return on investment (ROI) based on its durability and longevity.

Upfront Cost Compared To Other Flooring Options In Commercial Kitchens

The upfront cost of unglazed quarry tile may be higher compared to some other flooring options for commercial kitchens. However, it is crucial to consider the long-term benefits and cost savings that come with choosing this durable flooring material.

Unlike some other flooring options that may require frequent repairs or replacement, quarry tile is known for its longevity. With proper maintenance and care, quarry tile can last for decades, reducing the need for costly replacements.

Potential Return on Investment Based on Durability and Longevity

The durability and longevity of 6’’x 6’’ unglazed quarry tile contribute to its excellent ROI. By investing in a flooring material that can withstand the rigors of a commercial kitchen, business owners can avoid the expenses associated with frequent repairs or tile replacements.

Additionally, the slip-resisting properties of unglazed quarry tile help reduce the risk of accidents and injuries in the workplace.

When considering the ROI for unglazed quarry tile, it is important to evaluate the overall cost of ownership over the expected lifespan of the tile. Taking into account the durability, low maintenance requirements, and potential savings, it becomes clear that this flooring option offers a favorable return on investment.

Unglazed quarry tile offers numerous advantages for commercial kitchen flooring. Its durability, resistance to stains and moisture, slip-resisting resisting properties, and ease of maintenance make it an ideal choice for high-traffic areas. While the upfront cost may be higher compared to other options, the long-term benefits and return on investment outweigh the initial investment. By choosing six-inch unglazed quarry tile, business owners can create a safe and functional workspace while enhancing the overall appearance of their commercial kitchens.

Quarry Tile Flooring From Metropolitan Ceramics

Quarry Tile Flooring

When it comes to choosing the right type of tile for your business or even your home, there are many options to consider. One popular choice is quarry tile, which is favored by operators of demanding industries, such as commercial kitchens and food processing facilities.

Quarry tile is chosen for such applications because of its durability and resistance to moisture. However, not all quarry tiles are created equal. This blog post will compare Metropolitan Ceramics quarry tile to other manufacturers’ options. Let’s look at the Metropolitan Ceramics difference.

What Is Quarry Tile?

Quarry tile is a type of floor tile that is made from natural clay and shale. It is known for its hardness and ability to withstand extreme temperatures and moisture, which make it a popular choice for high-traffic areas like commercial kitchens, hallways and entryways, food processing plants, breweries, convenience stores, and more. It is a type of ceramic tile that is unglazed, which gives it a natural, rustic look. Quarry tile has a vitreous nature, making it suitable for outdoor applications as well. High-quality quarry tile, such as that from Metropolitan Ceramics also features a dynamic coefficient of friction well above the industry guideline of .42, helping to prevent slips and falls.

Quarry tile is produced in a variety of colors, from earthy browns, tans, and reds to more modern shades like gray and black. The tiles are solid, with the color running through the body of each tile.

Extruded vs. Pressed Quarry Tile

The method used to produce a quarry tile makes a big difference when it comes to its strength and quality. There are two ways to manufacture quarry tile: extrusion and pressing. Extruded quarry tile is made by forcing clay through a die. This process contributes to the product’s life expectancy of 50 years or more.

Pressed quarry tile is made by compressing clay into molds. This process can result in slight variations in size and thickness — a look some homeowners prefer. Both types of quarry tile are functional, but there are some differences to consider when choosing a tile.

Metropolitan Ceramics quarry boasts uniformity in size and thickness, which makes it easier to install evenly. Because of the pressure placed on the clay during the extrusion process, it is also less likely to have imperfections, such as air pockets or cracks, which can compromise the tile’s strength. Pressed quarry tile is less dense than extruded tile, which can compromise its durability and ability to resist moisture.

Another important difference when it comes to quarry tile strength is thickness. Metropolitan Ceramics quarry tiles have a thickness of ½ inch, whereas many other tiles have a thickness of only ¼ or ⅛ inches. The extrusion process, a method that Metropolitan Ceramics company has used in brick and tile making for more than 150 years, creates an extruded quarry tile that outperforms its pressed alternatives.

Metropolitan Ceramics Offer More Types of Quarry Tile

Metropolitan Ceramics offers four quarry tile product lines through our professional distributor networks:

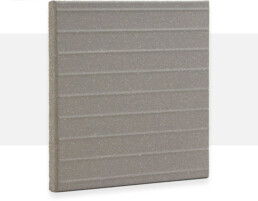

QuarryBasics® Ironspot: Integrates small iron particles throughout the tile body, resulting in a subtle speckled appearance, while still maintaining a Dynamic Coefficient of Friction ≥ .60 at time of manufacture. The unique blend of durability, along with a focus on safety and appearance, positions QuarryBasics Ironspot as the preferred option for demanding projects.

QuarryBasics® XA Abrasive: All the durability and slip-resisting properties of our QuarryBasics® line with a silicon-embedded surface and a metallic additive through the body of the tile to create a one-of-a-kind tile with added slip-resisting properties. This line is appropriate for the most challenging environments where slip prevention is essential.

The Metropolitan Ceramics Quarry Tile Investment

Metropolitan Ceramics puts its quarry tiles through rigorous testing so that we can offer a commercial flooring product that will remain undamaged and retain its aesthetics and safety characteristics for decades. The exceptional technical characteristics of our quarry tiles make them appropriate for virtually any application suitable for tile. We meet or exceed ASTM standards in 13 areas including abrasion resistance, breaking strength, freeze/thaw, shear bond strength, chemical resistance, stain resistance, and scratch hardness.

This means that quarry tile from Metropolitan Ceramics is your best investment when it comes to commercial flooring for challenging environments. Contact us to learn more about Metropolitan Ceramics quarry tile lines or find a distributor of our products.

Gray Quarry Tile: Enduring Style and Superior Functionality

When it comes to choosing the perfect flooring option for your demanding commercial environment, performance and timeless style can harmoniously coexist. In the world of tile, one option stands out for its superior functionality as well as aesthetics: quarry tile.

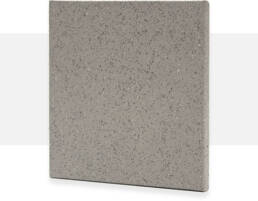

Its enduring nature can be attributed to its superior strength, but its attractive, natural colors and texture also make it an attractive option. Neutral iterations of this material, such as gray quarry tile, have become a go-to choice for both residential and commercial spaces. In this blog post, we will explore the many reasons why gray quarry tile is a widely-selected product in the flooring market.

Gray Quarry Tile: Contemporary Hues for Workhorse of Tile

Although its name suggests something that comes straight from the earth, quarry tile is actually made from clay and shale that are fired at high temperatures, resulting in an extremely hard-wearing surface. Quarry tile comes in a handful of earthy colors. Different hues are produced by altering the natural raw materials put into the “recipe.” Tiles with a base of shale generally have a red or brown color. Grays and beiges, both popular choices in contemporary architecture and design, typically have a clay base. The distinctive unglazed finish of gray quarry tile, as well as that of its red and brown counterparts, adds authenticity and character to any space. While many commercial kitchens once favored red and brown shades of quarry tile, newer projects, from restaurant kitchens to food manufacturing plants are now opting for shades of gray. None of the durability is compromised from color to color.

The Benefits of Quarry Tile: Functionality Meets Durability

Quarry tile offers benefits that make it a popular choice for commercial spaces. Its functionality and durability are unmatched, making it an ideal flooring option for high-traffic areas, or spaces that see extreme temperatures, such as freezers or kitchens in which very hot equipment or spills, such as hot grease, are a factor.

Metropolitan Ceramics’ quarry tile owes its superior durability to high-quality clay and minerals as well as our time-tested manufacturing process. Our parent company’s brick-making tradition began just after the Civil War, and our quarry tile operation, which began in the 1970s, borrows heavily from brick-making. Our quarry tile, like brick, is formed through an extrusion process. Unlike lesser products pressed into a mold, our quarry tile is pushed through a machine under very high pressure, a process that extracts the most water. The more moisture that is removed in the formation process, the less absorbent each tile is, which translates to a stronger and more durable quarry tile.

After extrusion and cutting, our quarry tiles are then dried and kiln-fired at temperatures that exceed 2000 degrees Fahrenheit — hotter than the temperature at which other ceramic tiles are fired. The high temperature increases the density of quarry tile, which helps the product resist moisture, oils and greases, mold and bacteria growth, stains, and scratches. Most importantly for environments like commercial kitchens, quarry tile’s density and unglazed finish make its surface texture naturally slip-resisting. It is the right choice for wet conditions.

The extensive production process and the attributes of quarry tile make it a more expensive option upfront, compared to some other options, such as laminate or sheet vinyl. However, an independent study from the Tile Council of North America that examined lifetime costs of various commercial flooring materials found quarry tile had the lowest cost per year over the lifespan of the floor. Moreover, despite the superior lifespan of quarry tile, it is a less expensive option than alternatives such as poured epoxy or ceramic.

Another important feature of quarry tile is its ability to withstand extreme outdoor or indoor temperatures. It stands up, year after year, to the scorching sun as well as the punishing environments of walk-in freezers and Northern winters. This is partly because quarry tile does not absorb water the way many other flooring materials do. Therefore, our tiles do not crack when the absorbed water freezes.

In terms of style, gray quarry tile is both on-trend at the moment and has a timeless neutrality that can complement most design aesthetics. It provides a versatile basis for any color scheme, especially when brown undertones are present in the gray tile.

Maintaining quarry tile is a straightforward process, requiring daily sweeping or vacuuming and mopping. To mop, combine two gallons of hot water and four ounces of Hillyard Assurance® cleaner. For the QUARRYBASICS XA Abrasive Series the use of a nylon/poly looped end mop is recommended.

With proper installation and care, quarry tile can withstand heavy use for decades while maintaining its timeless appeal.

Design Inspiration: Quarry Tile is a Building Block

Gray is an excellent choice when it comes to quarry tile colors. Styles change. While you might be trying to create a rustic look today, in the future, your tastes might veer toward something more modern. Gray quarry tile can shift with you. Whether used in residential or commercial environments, this versatile option offers both style and practicality.

Gray is an excellent choice when it comes to quarry tile colors. Styles change. While you might be trying to create a rustic look today, in the future, your tastes might veer toward something more modern. Gray quarry tile can shift with you. Whether used in residential or commercial environments, this versatile option offers both style and practicality.

Gray quarry tile is the perfect, on-trend choice not only for commercial kitchens but for any environment where durability and safety are non-negotiable, but contemporary style is desired as well, such as convenience stores, or automobile showrooms. Quarry tile also makes an ideal fireplace surround, offering warmth, sophistication and superior heat resistance. Outdoors, gray quarry tile makes a safe, durable patio material.

With its ability to blend seamlessly with different design styles, gray quarry tile allows you to create a cohesive look throughout your home or business. Whether you are going for a classic aesthetic or contemporary vibe, this versatile flooring material can help bring your vision to life.

Metropolitan Ceramics Offers an Array of Gray

Metropolitan Ceramics, with a history that dates back more than 150 years, is a leading producer of quarry tile and thin brick products. We are proud that millions of square feet of our quarry tile has been installed throughout the United States.

If it is gray quarry tile you are looking for, we have your color in one of our QuarryBasics® lines of unglazed ceramic quarry tile. QuarryBasics® products are the foremost natural, unglazed, high density ceramic quarry tile made in the U.S.A. These tiles are extruded, not pressed, and fired in kilns at extremely high temperatures to create quarry tile that is very low absorption (vitreous), slip-resisting, and extremely durable. Metropolitan Ceramics’ QuarryBasics® quarry tile meets or exceeds eight durability tests, including breaking strength and abrasion resistance.

We offer gray tones in a Pewter 6″ x 6″ tile; a nearly-black Raven option in 4″ x 8″, 6″ x 6″, and 8″ x 8″ sizes; and a Puritan Gray shade with black speckling throughout the body of the tile and on the surface in a 6″x6″ tile.

Reach out to Metropolitan Ceramics today for more information about incorporating this functional, naturally beautiful tile into your project.

Ironrock Begins Refractory Recycling Program

Refractories are the plates, posts, and blocks that let our tile and brick go through our kilns. Although they can withstand high temperatures, they are easy to break. Each year, we replaces broken refractories. In the past, broken refractories have been crushed into aggregate along with fired scrap but recently we began a program to return them to our local refractory supplier to use as grog. Grog is ground up refractories that help new refractory pieces use less energy and material to fire and produce. This helps our supplier because they need more grog.

Ironrock is pleased that our broken refractories will be re-used to make new refractories and add to the list of materials we recycle and re-use.

Learn more about Ironrock's recycling program.

Metropolitan Ceramics Meets & Exceeds New Slip Resistance Designations

For many years, the 0.42 Dynamic Coefficient of Friction (DCOF) measurement has been the industry-accepted norm for interior, horizontal surfaces that can be expected to be wet. Now there are also five designations, Interior Dry, Interior Wet, Interior Wet Plus, Exterior Wet, and Oils and Greases incorporated into the standard.

Areas of Use

We have included an additional category beyond the scope of A326.3 which we are calling “Enhanced Grip”. All products are routinely used in the five categories listed but products that include our Quarry Basics® XA-Abrasive and our Metro Tread® can be used in even more demanding applications such as ramps. We encourage you to contact us with your specific application to find out which Metropolitan Ceramics product is suitable for your needs.

Join Ironrock's Sr. VP of Operations, Daniel Marvin, as he examines slip resistance and the NEW Areas of Use Table - ANSI A326.3

Metropolitan Quarry Tile, MetroBrick, and Royal Thin Brick Added to mindful Materials database

Ironrock is pleased to announce that all quarry tile and thin brick product lines are now listed in the mindful Materials database. Launched in 2014 by several major architectural firms and sustainability groups, mindful Materials has grown to be the database of choice for thousands of Well Building, Living Building Challenge, and LEED v4 projects each year. The database provides a one-stop-shop for all sustainability certifications and information associated with the products listed there.

Ironrock is pleased to announce that all quarry tile and thin brick product lines are now listed in the mindful Materials database. Launched in 2014 by several major architectural firms and sustainability groups, mindful Materials has grown to be the database of choice for thousands of Well Building, Living Building Challenge, and LEED v4 projects each year. The database provides a one-stop-shop for all sustainability certifications and information associated with the products listed there.

“For over 150 years, Ironrock has produced ceramic products in the most sustainable way while providing our customers the information they want to make informed choices about what they are buying,” says Guy Renkert, the 5th generation of the Renkert family to helm the company. “Adding our products to the mindful Materials database is a great way to highlight our Green Squared multi-attribute certification, our EPD, and our Manufacturer’s Ingredient Disclosure in a way that designers and architects can easily access them.”

“While the information is on our website,” adds Ron Williamson, Director of Marketing for Ironrock, “it is only available to designers that already know about us. By adding our products to mindful Materials we are able to immediately be visible to anyone working on sustainable projects. We are especially excited to be the first ceramic brick manufacturer to list our products there.”

Ironrock is a family-owned manufacturer of quarry tile and thin brick products based in Canton Ohio. More for information about the products mentioned here visit www.metroceramics.com.

What is Unglazed Quarry Tile?

I started my career in the tile industry when the ‘new millennium’ was still a decade away. If you had told me back then that one day I would be writing a blog titled ‘What is Quarry Tile?’ I would have scoffed. And then asked ‘what is internet?‘ Yet, here we are.

I started my career in the tile industry when the ‘new millennium’ was still a decade away. If you had told me back then that one day I would be writing a blog titled ‘What is Quarry Tile?’ I would have scoffed. And then asked ‘what is internet?‘ Yet, here we are.

The company I worked for then made all four kinds of tile – ceramic mosaics, glazed wall tile, pressed floor tile, and quarry tile.

Mosaics were little and went in locker rooms and pools. Wall tiles were 4 1/4″ squares that sometimes were blue or gold or green but usually were white. Pressed floor tiles got up to 12″ square if you were really wild and had the same repeating pattern screen printed on every one. And then there was quarry tile. Durable, eternal, and available in a rainbow of earth tones, quarry tile was well known and understood.

You can still find all of these tiles of course, but they’ve been joined by countless sizes, shapes, and decorating techniques until the distinctions have become blurred. Many designers and installers today are not aware of what sets quarry tile apart from other types of tile. I will be blogging about what it is and how to install it. Today we will look at what quarry tile is:

The textbook definition – Our old friend, the Tile Council of North America Handbook defines it this way: Quarry tiles are ceramic tiles for floor and wall applications made by the extrusion process from natural clay or shale. The ANSI standard specifications for ceramic tiles offer some additional guidance pointing out that quarry tiles are allowed more size and warpage variation than porcelain tiles and can have up to 5% absorption.

The practical definition – The textbook definitions are designed to allow for a large variety of similar products to be defined as quarry tile. From a practical standpoint, the things you will want to know are:

Extruded – Quarry tile is extruded. That means the clay is mixed together and pushed with an auger through a die opening and then cut with a cutter to the proper size. This matters from a practical perspective because extruded tiles form a durable ‘die skin’ on the surface that helps with chemical and stain resistance.

For more information on how quarry tile is made, see our Youtube video.

Vitreous – Although ANSI allows up to 5% absorption, for most applications you will want quarry tile that is considered vitreous which means it has less than 3% absorption. This helps the tile withstand freeze-thaw cycles outside and staining inside.

Unglazed – Although there are glazed quarry tiles out there, the vast majority of quarry tile is unglazed. That means there is no glaze to chip off and if the tile does wear, the color under the surface is the same as the color on top.

Chemical and stain resistant – Unlike some porcelains and most wall tiles, quarry tile is not easily etched or stained by common chemicals. You will typically find it used in commercial applications like commercial kitchens and breweries.

Slip Resistant – Along with chemical resistance, quarry tile has a high coefficient of friction which improves traction. For the most rigorous slip resistant flooring applications, versions are available with tread patterns and abrasive grains.

There are other considerations that are important for quarry tile such as having the right trim shapes available for sanitary requirements and barrier free (ADA) regulations. For now you have the basics, quarry tile is an unglazed, extruded tile made out of clay that should have less than 3% absorption so it can go in demanding environments where chemical and slip resistance are important considerations. In our next post, we will take a look at some of the installation requirements for quarry tiles.

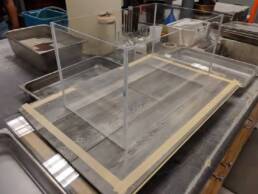

Don't use this type of grout for Commercial Kitchens

Single component grouts that can be scooped directly from the bucket and applied to tiles have become increasingly popular over the last 10 years. These ready to use grouts are great for many applications, but should never be used in commercial kitchens even if the advertisement says they offer ‘all of the benefits‘ of epoxy grout. They aren’t epoxy grouts and the differences are most obvious in a commercial kitchen setting. All of them exclude environments where harsh chemicals are used in their Technical Data Sheet.

Quarry tile is the most popular floor covering for commercial kitchens because it is very resistant to anything you can throw at it. The grout you pair with the quarry tile needs to be equally resistant to harsh cleaners, grease, and other conditions found in this environment. The enzymatic cleaners typically used for commercial kitchens are designed to digest fat and grease particles with enzymes. While the best practice is to then rinse these cleaners from the floor, often that is not done. This creates oleic acid that can damage cement grout, standard epoxy grout, and single component grouts.

For commercial kitchens, Metropolitan recommends the use of 100% solids epoxy grouts designed specifically for this type of application. Generally these are advertised as industrial epoxy grouts. Common grouts in this category include Kerapoxy IEG from MAPEI, Spectralock 2000 IG from Laticrete, and CEG-IG from Custom Building Products. There are others available as well. These grouts take practice to install as they are often stiffer and more challenging to clean than standard epoxy grouts. However, they are much easier to work with than the old technology, furan grouts. When in doubt, consult the installation products manufacturer to get their grout recommendation for your installation.

What is 'waterproof flooring?

Every day on my way to work, I hear a commercial on the radio offering a variety of floor coverings for sale including ‘waterproof flooring.’ They are talking about vinyl (plastic) flooring which has been around forever in some form or another. However, the plastic flooring industry has recently amped up their marketing machine with some crazy claims. I always grit my teeth because I know that most people hearing that ad won’t realize that the installed floor won’t be waterproof due to the seams. How do I know this? Because I sat in on a very interesting session on this topic given by Eric Astrachan at Coverings this year.

Testing the claims. In his talk, Eric showed a number of slides titled PBM Preliminary Research detailing the claims vs the reality. PBM in this case means “Plastic Based Flooring” and for the sake of the report includes LVT (luxury vinyl tile), LVP (luxury vinyl plank), RCB (rigid core board) and a host of other trendy three-letter acronyms the plastic flooring industry is fond of coining. Ten of these popular products were tested with two standard ways (one US standard and one from Europe) of determining if a system is waterproof. Ten of these popular products failed to stop water from passing through the seams into the subfloor below. If you install the worst performer in your bathroom and your tub overflows while you are at work, almost 50 gallons of water an hour would pass through the plastic flooring into your subfloor. That’s not waterproof or even close to it. Of course, the warranty for these products excludes this type of damage. Some even exclude damage from damp mopping.

Along with water comes – mold. By simulating water trapped under the tiles, it didn’t take very long for mold to start to grow in 90% of the samples tested. The plastic materials in the planks provide a perfect buffet of organics for mold to grow and thrive. Chances are good that if you leave a spill on your plastic floors for more than a few minutes, water will make its way under the tile and find a perfect situation to develop mold, mildew, and VOCs. If you like gross mold pictures, Eric’s report at the link above is full of them.

It doesn’t get better from there. You will often see plastic flooring described as ‘wear resistant’, ‘non-slip’, and even ‘life proof.’ Dogs run across the floors, kids roll toys on them and bathtubs overflow in the ads. Eric’s report goes on to debunk all of these claims. In the fine print you’ll find that the manufacturers tell you not to walk on the products wet. Why? Because they’re slippery when they get wet. Hmm. Likewise these products scratch easily. On the Mohs scale, most of them rate no higher than 3 which is very soft – maybe you’re better than me at keeping your dog’s nails trimmed but yep, Fido can scratch most plastic flooring.

If something sounds too good to be true, read the fine print. There is a lot of fine print with plastic flooring. Water from ‘flooding’ (ie – overflowing bathtubs)? Excluded. Scratching from your pet’s nails? Excluded. Indentations from furniture? Excluded unless you use furniture pads. You DO use furniture pads under all of your table legs, right? Slipping while wet? Excluded. Trust me, I’ve written many product warranties and I would not have wanted my name associated with any of these. The ‘new’ plastic floors are just like the old ones – good for dry areas you don’t walk on. Anything beyond that? Excluded.

Black is Always a Popular Design Choice

Is black a color? Some say yes, some say no. In color theory, the mixture of black with a color is called shading – a reduction in lightness. When discussing colors, black is both described as the absence of color and absorbing all color. To an artist, black is often seen as a coloring agent the same as the rest of the colors in a palette and is considered a color.

Whether you think of black as a color or shade, the absence of color or absorbing all colors, one thing is for sure, shades of black are still essential options in the world of design.

All types of industries use black and shades of black, from fashion to automobiles to building design and interiors. The introduction of black in design can create many positive responses.

Black can represent a number of emotions and characteristics including authority, power, sophistication, mystery, stability, strength, intelligence, seriousness, and power. Black is so essential in the fashion industry that “the new black” refers to any new color trend. Sports franchises incorporate black in their uniform designs to indicate power. Black automobiles are the leading sellers in the luxury category.

Interest in black finishes has gained even more popularity in the last few years. In the floor and wall tile category black and near black are used in conjunction with other materials as part of a pattern, as an accent, and in full coverage applications. Commercially, restaurants, for example, are adding intimacy and elegance to their spaces with designs incorporating black elements. Building exteriors too are turning to black cladding to create industrial and modern motifs.

In keeping with the requests from designers and architects for black product options for their projects, Metropolitan Ceramics has both tile and thin brick colors available in black shades.

Metropolitan Ceramics’ Raven color is a through-the-body black quarry tile available in 4” x 8”, 8” x 8”, and 6” x 6” size. Raven has the same properties as Metropolitan’s other quarry products. Raven is perfect for adding the character of black to an installation without compromising slip resistance and durability.

Metropolitan Ceramics’ also offers black thin brick in modular size wire-cut and smooth finish as part of the Fast Ship product offering and in queen size tumbled thin brick as part of the Royal Thin Brick product line.

Available to all Metropolitan Ceramics’ distributors, black quarry tile and thin brick offerings are used for walls and floors – indoors and out, this kind of versatility is especially appealing.to the end user.

Black is an important color in interior design and architecture. Metropolitan Ceramics offers both quarry tile and thin brick in black to meet the demand with products that combine the aesthetics designers need with the durability the job demands.

Receive a FREE Metropolitan Ceramics sample binder and literature.