Ironrock Begins Refractory Recycling Program

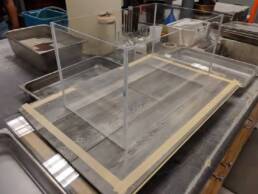

Refractories are the plates, posts, and blocks that let our tile and brick go through our kilns. Although they can withstand high temperatures, they are easy to break. Each year, we replaces broken refractories. In the past, broken refractories have been crushed into aggregate along with fired scrap but recently we began a program to return them to our local refractory supplier to use as grog. Grog is ground up refractories that help new refractory pieces use less energy and material to fire and produce. This helps our supplier because they need more grog.

Ironrock is pleased that our broken refractories will be re-used to make new refractories and add to the list of materials we recycle and re-use.

Learn more about Ironrock's recycling program.

Metropolitan Ceramics Meets & Exceeds New Slip Resistance Designations

For many years, the 0.42 Dynamic Coefficient of Friction (DCOF) measurement has been the industry-accepted norm for interior, horizontal surfaces that can be expected to be wet. Now there are also five designations, Interior Dry, Interior Wet, Interior Wet Plus, Exterior Wet, and Oils and Greases incorporated into the standard.

Areas of Use

We have included an additional category beyond the scope of A326.3 which we are calling “Enhanced Grip”. All products are routinely used in the five categories listed but products that include our Quarry Basics® XA-Abrasive and our Metro Tread® can be used in even more demanding applications such as ramps. We encourage you to contact us with your specific application to find out which Metropolitan Ceramics product is suitable for your needs.

Join Ironrock's Sr. VP of Operations, Daniel Marvin, as he examines slip resistance and the NEW Areas of Use Table - ANSI A326.3

Metropolitan Quarry Tile, MetroBrick, and Royal Thin Brick Added to mindful Materials database

Ironrock is pleased to announce that all quarry tile and thin brick product lines are now listed in the mindful Materials database. Launched in 2014 by several major architectural firms and sustainability groups, mindful Materials has grown to be the database of choice for thousands of Well Building, Living Building Challenge, and LEED v4 projects each year. The database provides a one-stop-shop for all sustainability certifications and information associated with the products listed there.

Ironrock is pleased to announce that all quarry tile and thin brick product lines are now listed in the mindful Materials database. Launched in 2014 by several major architectural firms and sustainability groups, mindful Materials has grown to be the database of choice for thousands of Well Building, Living Building Challenge, and LEED v4 projects each year. The database provides a one-stop-shop for all sustainability certifications and information associated with the products listed there.

“For over 150 years, Ironrock has produced ceramic products in the most sustainable way while providing our customers the information they want to make informed choices about what they are buying,” says Guy Renkert, the 5th generation of the Renkert family to helm the company. “Adding our products to the mindful Materials database is a great way to highlight our Green Squared multi-attribute certification, our EPD, and our Manufacturer’s Ingredient Disclosure in a way that designers and architects can easily access them.”

“While the information is on our website,” adds Ron Williamson, Director of Marketing for Ironrock, “it is only available to designers that already know about us. By adding our products to mindful Materials we are able to immediately be visible to anyone working on sustainable projects. We are especially excited to be the first ceramic brick manufacturer to list our products there.”

Ironrock is a family-owned manufacturer of quarry tile and thin brick products based in Canton Ohio. More for information about the products mentioned here visit www.metroceramics.com.

What is Unglazed Quarry Tile?

I started my career in the tile industry when the ‘new millennium’ was still a decade away. If you had told me back then that one day I would be writing a blog titled ‘What is Quarry Tile?’ I would have scoffed. And then asked ‘what is internet?‘ Yet, here we are.

I started my career in the tile industry when the ‘new millennium’ was still a decade away. If you had told me back then that one day I would be writing a blog titled ‘What is Quarry Tile?’ I would have scoffed. And then asked ‘what is internet?‘ Yet, here we are.

The company I worked for then made all four kinds of tile – ceramic mosaics, glazed wall tile, pressed floor tile, and quarry tile.

Mosaics were little and went in locker rooms and pools. Wall tiles were 4 1/4″ squares that sometimes were blue or gold or green but usually were white. Pressed floor tiles got up to 12″ square if you were really wild and had the same repeating pattern screen printed on every one. And then there was quarry tile. Durable, eternal, and available in a rainbow of earth tones, quarry tile was well known and understood.

You can still find all of these tiles of course, but they’ve been joined by countless sizes, shapes, and decorating techniques until the distinctions have become blurred. Many designers and installers today are not aware of what sets quarry tile apart from other types of tile. I will be blogging about what it is and how to install it. Today we will look at what quarry tile is:

The textbook definition – Our old friend, the Tile Council of North America Handbook defines it this way: Quarry tiles are ceramic tiles for floor and wall applications made by the extrusion process from natural clay or shale. The ANSI standard specifications for ceramic tiles offer some additional guidance pointing out that quarry tiles are allowed more size and warpage variation than porcelain tiles and can have up to 5% absorption.

The practical definition – The textbook definitions are designed to allow for a large variety of similar products to be defined as quarry tile. From a practical standpoint, the things you will want to know are:

Extruded – Quarry tile is extruded. That means the clay is mixed together and pushed with an auger through a die opening and then cut with a cutter to the proper size. This matters from a practical perspective because extruded tiles form a durable ‘die skin’ on the surface that helps with chemical and stain resistance.

For more information on how quarry tile is made, see our Youtube video.

Vitreous – Although ANSI allows up to 5% absorption, for most applications you will want quarry tile that is considered vitreous which means it has less than 3% absorption. This helps the tile withstand freeze-thaw cycles outside and staining inside.

Unglazed – Although there are glazed quarry tiles out there, the vast majority of quarry tile is unglazed. That means there is no glaze to chip off and if the tile does wear, the color under the surface is the same as the color on top.

Chemical and stain resistant – Unlike some porcelains and most wall tiles, quarry tile is not easily etched or stained by common chemicals. You will typically find it used in commercial applications like commercial kitchens and breweries.

Slip Resistant – Along with chemical resistance, quarry tile has a high coefficient of friction which improves traction. For the most rigorous slip resistant flooring applications, versions are available with tread patterns and abrasive grains.

There are other considerations that are important for quarry tile such as having the right trim shapes available for sanitary requirements and barrier free (ADA) regulations. For now you have the basics, quarry tile is an unglazed, extruded tile made out of clay that should have less than 3% absorption so it can go in demanding environments where chemical and slip resistance are important considerations. In our next post, we will take a look at some of the installation requirements for quarry tiles.

Don't use this type of grout for Commercial Kitchens

Single component grouts that can be scooped directly from the bucket and applied to tiles have become increasingly popular over the last 10 years. These ready to use grouts are great for many applications, but should never be used in commercial kitchens even if the advertisement says they offer ‘all of the benefits‘ of epoxy grout. They aren’t epoxy grouts and the differences are most obvious in a commercial kitchen setting. All of them exclude environments where harsh chemicals are used in their Technical Data Sheet.

Quarry tile is the most popular floor covering for commercial kitchens because it is very resistant to anything you can throw at it. The grout you pair with the quarry tile needs to be equally resistant to harsh cleaners, grease, and other conditions found in this environment. The enzymatic cleaners typically used for commercial kitchens are designed to digest fat and grease particles with enzymes. While the best practice is to then rinse these cleaners from the floor, often that is not done. This creates oleic acid that can damage cement grout, standard epoxy grout, and single component grouts.

For commercial kitchens, Metropolitan recommends the use of 100% solids epoxy grouts designed specifically for this type of application. Generally these are advertised as industrial epoxy grouts. Common grouts in this category include Kerapoxy IEG from MAPEI, Spectralock 2000 IG from Laticrete, and CEG-IG from Custom Building Products. There are others available as well. These grouts take practice to install as they are often stiffer and more challenging to clean than standard epoxy grouts. However, they are much easier to work with than the old technology, furan grouts. When in doubt, consult the installation products manufacturer to get their grout recommendation for your installation.

What is 'waterproof flooring?

Every day on my way to work, I hear a commercial on the radio offering a variety of floor coverings for sale including ‘waterproof flooring.’ They are talking about vinyl (plastic) flooring which has been around forever in some form or another. However, the plastic flooring industry has recently amped up their marketing machine with some crazy claims. I always grit my teeth because I know that most people hearing that ad won’t realize that the installed floor won’t be waterproof due to the seams. How do I know this? Because I sat in on a very interesting session on this topic given by Eric Astrachan at Coverings this year.

Testing the claims. In his talk, Eric showed a number of slides titled PBM Preliminary Research detailing the claims vs the reality. PBM in this case means “Plastic Based Flooring” and for the sake of the report includes LVT (luxury vinyl tile), LVP (luxury vinyl plank), RCB (rigid core board) and a host of other trendy three-letter acronyms the plastic flooring industry is fond of coining. Ten of these popular products were tested with two standard ways (one US standard and one from Europe) of determining if a system is waterproof. Ten of these popular products failed to stop water from passing through the seams into the subfloor below. If you install the worst performer in your bathroom and your tub overflows while you are at work, almost 50 gallons of water an hour would pass through the plastic flooring into your subfloor. That’s not waterproof or even close to it. Of course, the warranty for these products excludes this type of damage. Some even exclude damage from damp mopping.

Along with water comes – mold. By simulating water trapped under the tiles, it didn’t take very long for mold to start to grow in 90% of the samples tested. The plastic materials in the planks provide a perfect buffet of organics for mold to grow and thrive. Chances are good that if you leave a spill on your plastic floors for more than a few minutes, water will make its way under the tile and find a perfect situation to develop mold, mildew, and VOCs. If you like gross mold pictures, Eric’s report at the link above is full of them.

It doesn’t get better from there. You will often see plastic flooring described as ‘wear resistant’, ‘non-slip’, and even ‘life proof.’ Dogs run across the floors, kids roll toys on them and bathtubs overflow in the ads. Eric’s report goes on to debunk all of these claims. In the fine print you’ll find that the manufacturers tell you not to walk on the products wet. Why? Because they’re slippery when they get wet. Hmm. Likewise these products scratch easily. On the Mohs scale, most of them rate no higher than 3 which is very soft – maybe you’re better than me at keeping your dog’s nails trimmed but yep, Fido can scratch most plastic flooring.

If something sounds too good to be true, read the fine print. There is a lot of fine print with plastic flooring. Water from ‘flooding’ (ie – overflowing bathtubs)? Excluded. Scratching from your pet’s nails? Excluded. Indentations from furniture? Excluded unless you use furniture pads. You DO use furniture pads under all of your table legs, right? Slipping while wet? Excluded. Trust me, I’ve written many product warranties and I would not have wanted my name associated with any of these. The ‘new’ plastic floors are just like the old ones – good for dry areas you don’t walk on. Anything beyond that? Excluded.